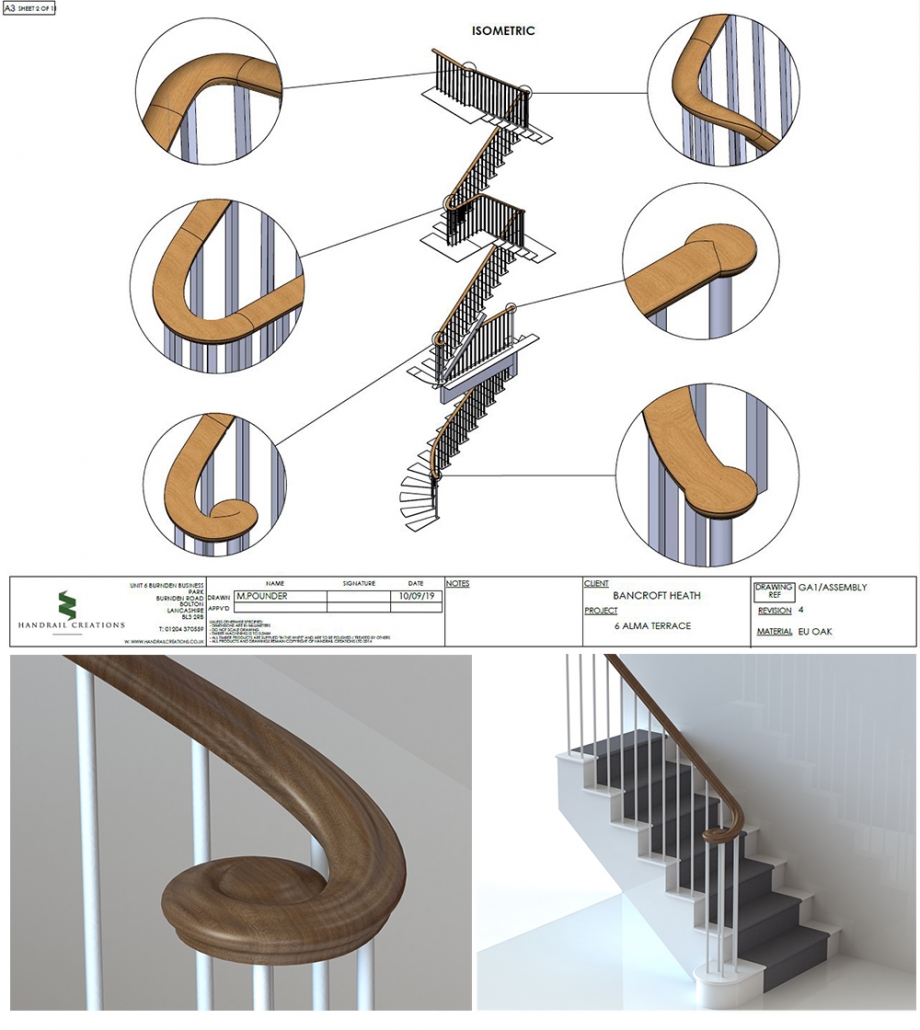

Handrail and Balustrade Design

Handrail Creations use state of the art CAD software and CAM systems to deliver the highest quality results on each of our made to measure handrail projects. Our award winning design team make the most complicated project seem straightforward. From our in house design studio, our team can share technical drawings, photo-realistic renders and installation guides so you know what you’re getting, before it’s made. Our staircase design works go hand in hand with our surveying abilities, developing and drawing everything from traditional wooden spindles to contemporary glass balustrade.

We work alongside architects, main contractors, staircase specialists and home owners to bring the latest handrail designs and balustrade concepts to life. This means that our design team cater for all requirements – supplying 3D models and as built drawings which comply with building regulations and within British Standards. Modern handrail design adds space, value and light to new homes and our design team will work alongside you to help bring your new staircase to life.

All of our CAM technicians are of the expertly trained and highly qualified. When it comes to programming the 5 axis CNC machines, our team simulates the manufacture of each piece prior to CNC cutting. This reduces waste and reduces risk, meaning you get your handrail first time, on time.

Take a look at what we can do on one of our recent projects here.

Handrail Manufacturing

Our 5 axis CNC facilities are one of a handful in Europe capable of producing such highly complex timber handrails. The state of the art machines are accurate to a fraction of a millimetre. The precision is to engineering standards. Our dedicated team of craftsmen work to a rigorous quality management system to ensure all parts are hand finished accurately and with care.

All of our hardwoods are sustainably sourced according to our environmental policy, and stored on site with a view to speeding up the production process. Before cutting, each of the prime grade timber boards are carefully selected (with minimum defects) and set on the CNC machine ready for milling. Once machined, the bespoke handrail parts are then inspected, and fine sanded.

We pre-joint, hand finish and assemble every component before it leaves the factory, so that there are no nasty surprises on site, saving you up to 80% on the fitting phase.

Time is money, after all.

Following a recent investment into machines, tooling and more staff, we can now produce more components, pro rata, than any other UK handrail supplier. This in turn, means reduced lead times for our clients.

Handrail & Balustrade Installation

Our experienced fitting teams have been installing wooden handrails for over 20 years. From a few steps in a theatre, to skyscrapers in London. Our craftsmen on site are qualified professionals who take pride in the finished product.

Our teams are all CSCS qualified and used to working under pressure, as we are often one of the final trades on site. We focus on both residential and commercial projects, specialising in:

Handrails and timber spindles, usually as part of a timber staircase

Handrail and steel spindles – installing to concrete stairs, stone stairs or timber staircases.

Handrails onto glass balustrade or steel core rail – balustrade fitted by others

Our teams work all over the UK and beyond, so if you have any doubts over if there is a handrail installer near me, then give us a call. Your project is in good hands.